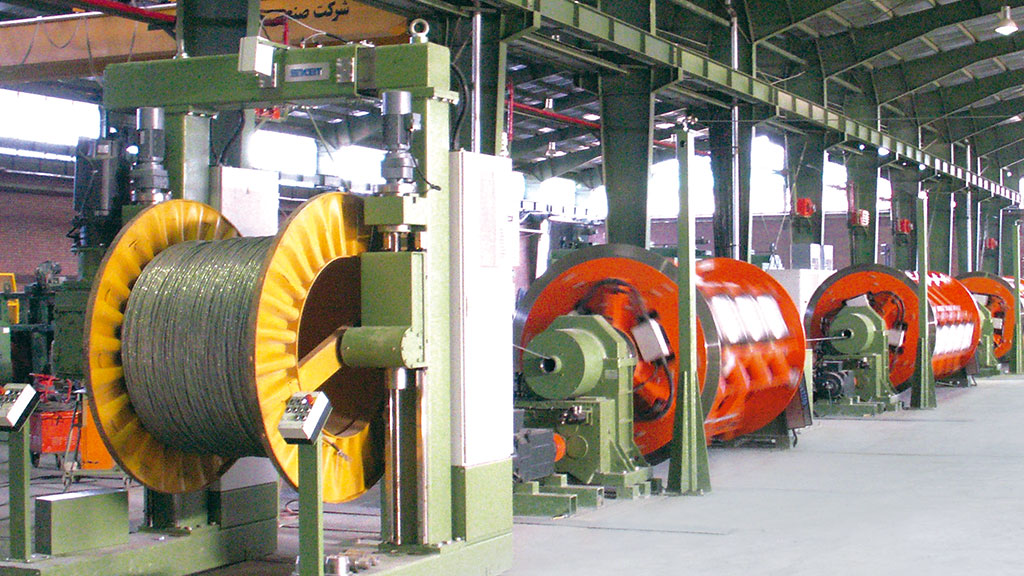

Rigid strander

without back-twist MKD

SKET Verseilmaschinenbau GmbH, located in Magdeburg, is a company with many years of experience in manufacturing rigid stranding machines. Rigid stranding machines occupy a key position in a comprehensive and wide range of machinery and equipment for the manufacture of cable and steel wire rope and figure prominently in the SKET delivery programme.

SKET rigid stranders are high-efficiency machines known for their reliability and suitability for a wide range of applications.

As is the case with all SKET machines, MKD rigid stranders are the subject of continuous further development so as to ensure that they offer an optimum solution to the current technological needs of cable manufacturers.

SKET rigid stranding machines are mainly used for the manufacture of:

- round and sector-shaped copper or aluminium wire compacted stranded conductors

- ACSR, AAC and AAAC overhead lines

- signal and control cables from stranded rubber or plastic insulated cores

- copper wire or flat aluminium wire screens

- round and flat steel armours

Machine Configurations

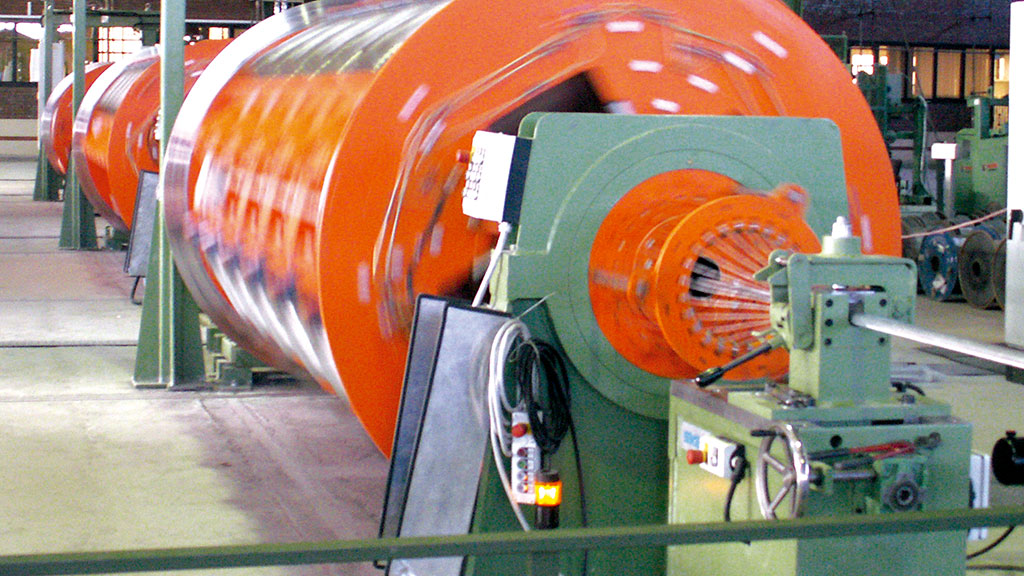

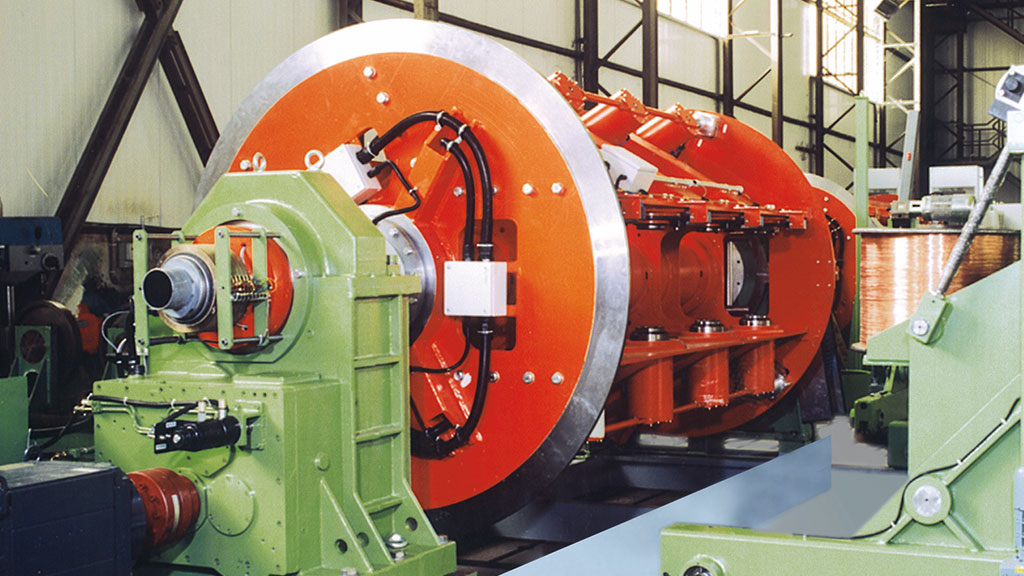

Stranding Cages

- compact design

- for bobbins having a flange diameter of 400, 500, 560, 630, 710 or 800 mm to DIN 46395

- suitable for separate or tandem operation

Arrangement of the Bobbins in the Stranding Cage

- in rows of 2, 4, 6, 8 and 9 bobbins

- for loading and unloading in sets

Machine Assembly Drives

- individual assembly drives using D.C. or A.C. technology

- speed and angular synchronization

Automatic Speed Increase

- enables the machine speed to be increased with bobbins getting empty

Bobbin Accommodation in the Stranding Cage

- bobbins accommodated on either side between pintles running in antifriction bearings designed to withstand the effects of centrifugal forces

- equipped with pneumatically controlled disc brake

- lifting of bobbins by spring force

- bobbin locking mechanism mechanically secured against opening

- braking force remaining constant while bobbin empties

Stranding Cage Braking

- stranding cages are brought to a standstill using disc brakes which, in conjunction with separate assembly drives, facilitate controlled braking of the machine

Wire Guidance

- from the bobbins to the stranding point, through ceramic ferrules or via ceramic-coated or hardened steel rolls

- when cages are used in tandem, via a system of steel tubes through the hollow shafts and via ferrules in the inlet and exit sections

Haul-offs

- of different capacities

- designed as single-capstan, dual-capstan or belt-type units

Pay-offs and Take-ups

- different sizes

- stationary or traversing design, or portal type

Guards

- free-standing fencing guards, guards designed to enclose the cage, electrically interlocked

Ancillary Equipment of different type

- preforming and postforming units

- stranding die holders and roller-type compactors for round or sector-shaped conductors

- tape applicators

Cage Loading and Unloading Systems

- to accommodate bobbins in sets and transport them to the cages for lateral loading and unloading of each cage

- underfloor-mounted stationary system for loading/unloading bobbins in sets