Tubular strander SRW

For many years high-speed tubular stranding machines have played the dominant roll in the wire rope industry and they are essential for the manufacture of steel wire strand and rope.

Used more and more for the closing of ropes, due to their greater effectiveness when compared to cage type stranding machines. Due to the ease of their handling during product changeover operations, high-speed stranding machines of all types are particularly flexible and suitable for users having continuously changing production programmes with a broad product spectrum and short production lengths.

SKET Verseilmaschinenbau GmbH in Magdeburg has many years of experience in the development and manufacture of stranding machinery and offers manufacturers of wire rope a wide range of such machines for the stranding of steel wires and steel wire strands. Continuous development and the further improvement of already well proven machine systems with purpose designed special assemblies, together with variability in numbers of machine bobbins, have led to a considerable increase in areas of application in the wire rope industry. Optimum tube design and manufacturing methods, the use of encircling bearings, new braking materials for wire and strand tension control and wire guides and guide materials designed specifically to suit the requirements of stranding technology, combine to ensure constant and relia-ble operation and the excellence of the finished product quality.

Areas of application

SKET high-speed tubular stranding machines are used mainly for the production of:

- compacted and non-compacted strands made from bright, galvanized or stainless steel wire

- compacted or non-compacted ropes manufactured from steel wire strands

- conveyor belt insert ropes

- pre-stressed and non-stressed elevator ropes

- Bowden strand

- Special ropes

Machine Configurations

High-speed tubular stranding machine for the production of strand and rope, consisting of:

- pay-off

- rotor and bearing assembly

- stranding section

- haul-off

- take-up

High-speed tubular stranding machine for the production of strands in various constructions and suitable for use as two separate machines or as a single machine running the two machines in tandem

High-speed tubular stranding machine with stretching unit for the manufacture of elevator ropes

High-speed tubular stranding machine with additional bull-head pay-off for the manufacture of Bowden cable and special ropes

High-speed tubular stranding machine with bobbin backtwist drive for the closing of steel wire rope

Technological Features

State of the Art Stranding Rotor Technology

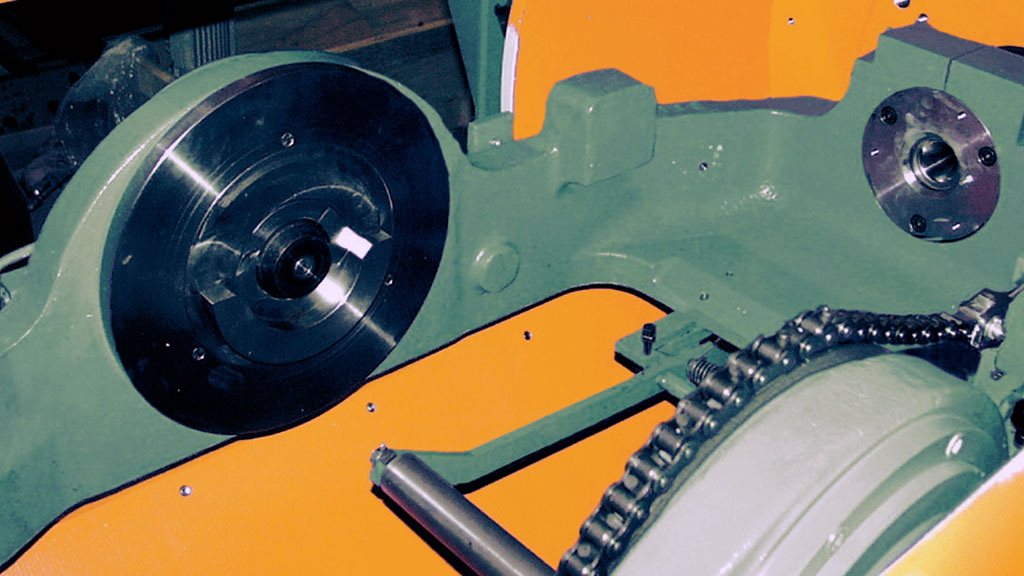

The stranding tubes consist of a number of tube sections, which are housed in encircling bearings resulting in high speeds, low power losses and simplified maintenance. Dependent on the size of the bobbin, the tubes accommodate up to four bobbins per section. The lubrication and the temperature of the bearings is continuously monitored.

Bobbin tension systems are designed to suit the needs of the particular requirements. The following systems are available:

- standard bobbin brakes have a braking chain with virtually wear free Teflon brake blocks or a Kevlar brake rope

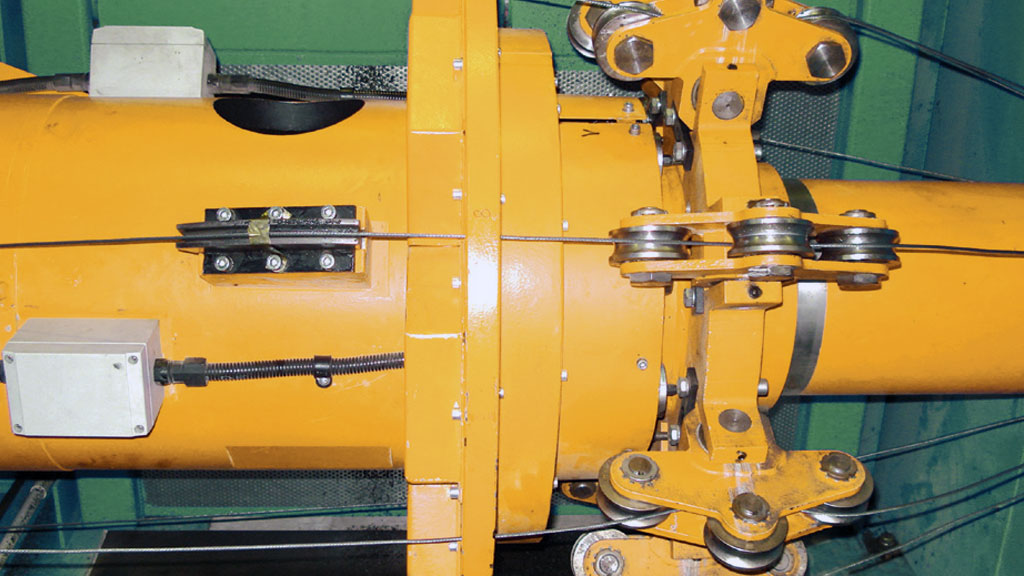

- mechanical bobbin brakes controlled via a contact roller

- mechanical bobbin brakes which are controlled via a spring loaded dancer

- mechanical bobbin brakes which can be varied from the control desk during the operation of the machine via an electrically operated cylinder

- electric bobbin brakes to provide automatic tension variation

The machines can also be fitted with gauges to measure and display tensions in the materials being stranded.

State of the Art Drive and Automation Technology

- machines are driven by frequency controlled three-phase motors, providing separate drives to the stranding rotor, haul-off and take-up assemblies meaning that gears and transmissions are no longer required for this purpose

- digital control technology enables the infinitely variable lay-length to be set from the control desk

- speeds can be infinitely varied from the control desk position during the operation of the machine

- touch screen control via programmable controllers provides fully automatic process control and operation, machine monitoring, programme management, data recording and storage, service functions and maintenance

- speed and angle synchronisation, torque- and traction control

- maintenance of all product related quality parameters at all times ensured by controlled machine braking, including in the event of an electrical failure (AC drive versions)

State of the Art Ancillary Equipment

Essential for the performance of a high speed stranding machine are:

- stationary, rotating or traversing pay-offs and take-ups accommodating bobbins having a flange diameter of up to 3,000 mm

- haul-off technology based mainly on double-capstan haul-offs, tailored to the requirements of the customer and having a pull of up to 400 kN

- pre- and post-formers to suit the technological characteristics of the stranding material or finished product

- calibrating- and compacting equipment

- strand- and rope lubrication equipment

- strand tension measurement equipment